Under Tile Waterproofing Restores Pacific Northwest Estate

by Vince Outlaw

- October 3rd, 2017 /

- Project Profile

Under tile waterproofing is an essential but sometimes overlooked component in new and renovation construction projects. If not specified and installed by trusted building partners from the start, it can lead to costly renovations and repairs as water naturally seeps under tile and damages plywood substrates not properly waterproofed. Westcoat’s architectural, technical, and inside sales representatives and staff work with owners, architects, builders, contractors, and specialty applicators for the right solutions to restore and protect your investment.

Specifying Under Tile Waterproofing Perfection

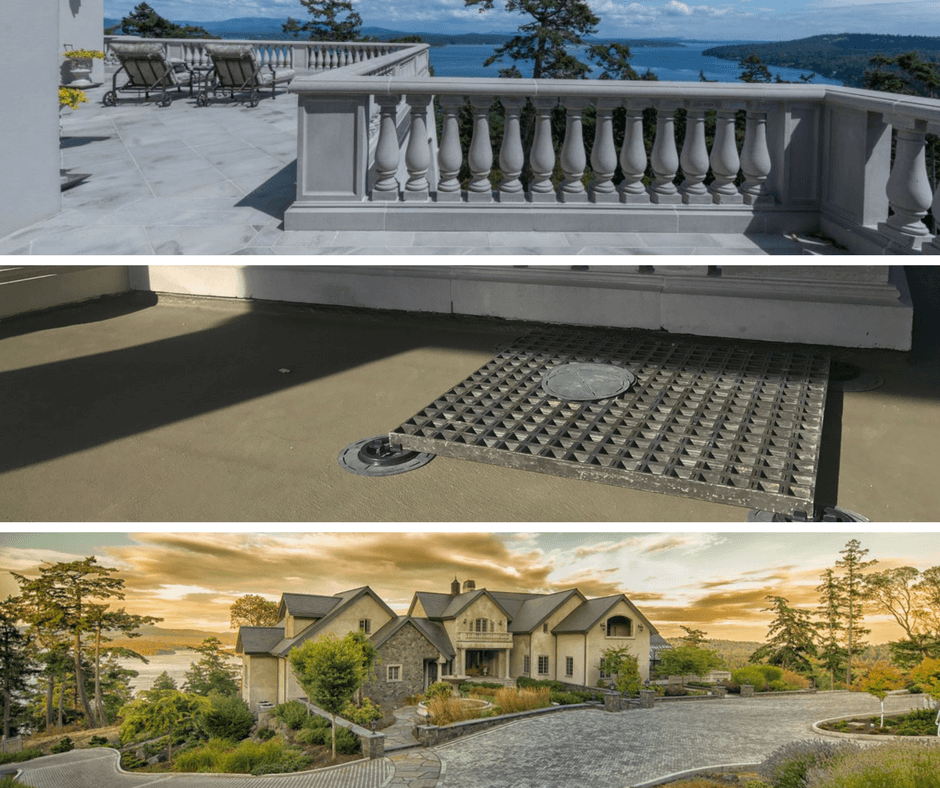

When the former President of Dole Food Company, Michael Carter, needed a under tile waterproofing expert for his Eagles Nest Estate, word of mouth guided him to Westcoat’s Pacific Northwest Architectural Rep, Rob Bechtel. Expert advice and long-lasting solutions are what makes Rob the go-to rep throughout the region. It was a perfect match, especially as Mr. Carter has very singular criteria for work on Eagles Nest, which he summed up in a Puget Sound Business Journal feature on Eagles Nest, “I built this as a spec development,” Carter said, “but spec with only perfection accepted. In fact a carved wood plaque on the property says ‘Perfect is acceptable’.

Mr. Carter built his custom estate on San Juan Island that lies between Seattle and Vancouver. The area is beautiful but experiences heavy rainfall and snow. The original under tile waterproofing system, installed in 2009, was failing on the estate’s 3 decks that total 3,200sq ft. The tile originally chosen to cover the decks is exquisite and Mr. Carter wanted to ensure it would not have to be torn out and replaced so soon again. The estate is built to exacting standards and there is no better system than Westcoat’s plywood waterproofing system, ALX, designed specifically for under tile installations to protect both the residents and the new tile that was to be installed. The team also decided to provide added protection and strength to the reinforced metal lath ALX system via an additional fiberlath resin membrane layer, the ALX Pro option. This additional layer provides greater waterproofing and helps protect against cracking, especially on larger spans or cantilever decks. The “Perfect” solution!

Rob Builds The Under Tile Waterproofing Team

Rob worked with both the general contractor, Long Phamily Construction, and Westcoat Qualified Contractor/Applicator (QCA) BBH Construction Services, on the best approach for the project including drain details. The team that Rob put together were very familiar with each other, having worked together on projects for 6 years. BBH Construction was also very familiar with Westcoat coating systems, having over 10 years of experience installing across the whole range of waterproofing, epoxy coat, surface coat, and texture coat system categories and exclusively installing Westcoat systems. When asked about how the project came together, BBH said “Rob brought us all in on this project, it was his connection and his approach that the home owner liked and followed from day one.” The team came together with the owner as one unit, or as BBH put it, “Working as a true team and getting the project done right not just on time.”

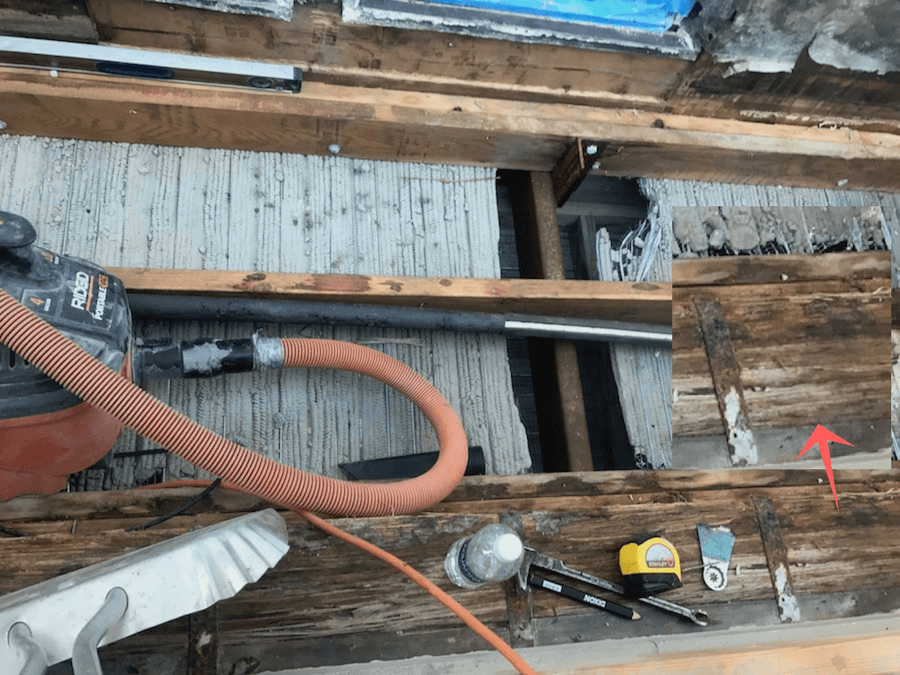

Rotten Wood Transformed To Strong Under Tile Waterproofing

The old tile was removed revealing severe wood rot. Once that was removed and replaced, new Thunderbird drains were placed and the ALX Pro UT system was installed. Starting with Westcoat’s WP-40 waterproofing membrane at full-coverage, followed by WP-25 Metal lath, then the Base Coat was applied. Once dry, the WP-47 Fiberlath Resin Membrane was applied. This consists of our fiberlath reinforcing mesh covered in a mixture of TC-1 cement and WP-90 Waterproofing Resin. The system is then completed with the Slurry Coat and is ready to accept the tile placement. See the whole plywood waterproofing system application process on our ALX training video page.