New Cookie-ng Facility for Kelley’s Kookies

by Christina

- December 6th, 2022 /

- Project Profile

Kelley’s Kookies started out as a simple home business selling to friends and family in 1988. The company’s popularity grew beyond the capacity of a home kitchen, soon leading to the opening of its first store in Cypress, California in 1993. Further company growth allowed Kelley’s Kookies to open more locations throughout California and Seattle, Washington areas.

Project Details

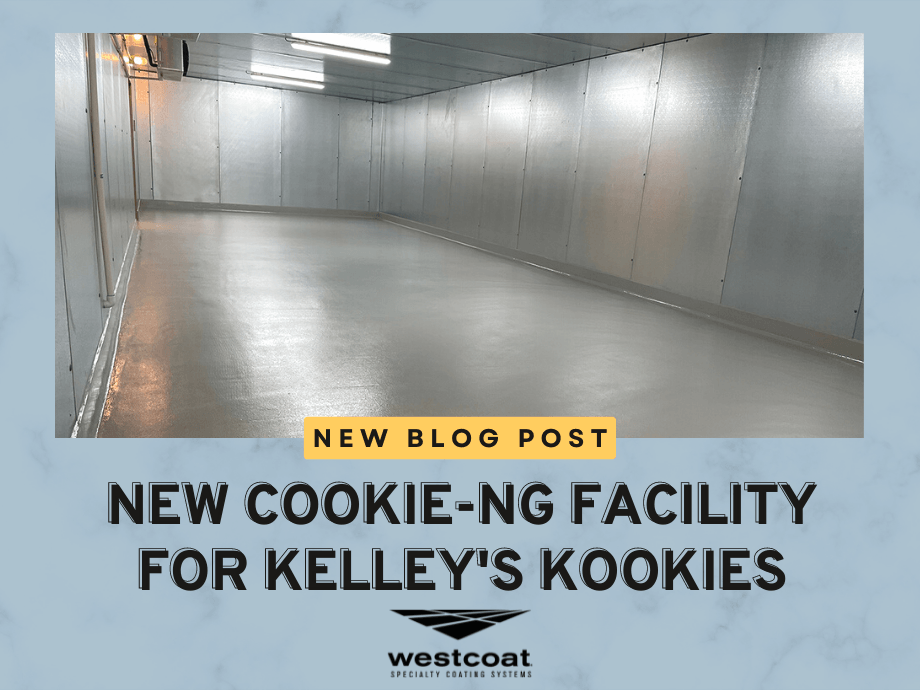

A new location recently opened in Los Alamitos, California. The client consulted Westcoat to apply our solutions to the kitchen floors. Westcoat rep Bill England recommended the use of Temper-Crete Broadcast to be installed by Westcoat QCA Pacific Coast Contracting Services.

The cookie manufacturing facility required full Temper-Crete Broadcast System. The existing Epoxy Mortar System at its new location needed a new topcoat of EC-102 (in Cape Cod Gray) for further protection. The new coating and existing coatings needed to be uniform. A system and cove sample were submitted to the OC Health Department for final approval.

The final result is an attractive and durable finish for an upcoming busy kitchen!

About Temper-Crete™

Westcoat’s Temper-Crete™ Broadcast System is a monolithic, flowable, urethane cement that can be installed with limited downtime. The Temper-Crete™ Broadcast System has an excellent impact, chemical, and heat resistant qualities. The Temper-Crete™ Broadcast System features an integral colored urethane cement base with decorative aggregate broadcast and polyaspartic topcoat. It offers a variety of decorative finish options and is designed for areas with heavy foot and moderate wheel traffic.

Uses

Temper-Crete™ Urethane Cement System is used to create a medium-duty, industrial, seamless floor in service areas, where a high build, self-leveling, and fast turnaround floor system is required.

Advantages

- USDA Compliant

- Thermal Shock Resistant

- Low Odor

- High Compressive Strength

- High Build

- Fast Turnaround

- Heat Resistant

About Epoxy Mortar

Westcoat’s Epoxy Mortar System is a 100% solids epoxy, combined with graded sand and troweled into place. It provides a high build system that is highly impact resistant, chemical resistant, and very durable.

Uses

Epoxy Mortar is used to create seamless floors in manufacturing plants, mechanical rooms, warehouses, commercial kitchens, restaurants, garages, and service areas where heavy use, such as forklift traffic, occurs. The Epoxy Mortar System is designed to be used as a heavy duty coating.

Advantages

- USDA Compliant

- Impact Resistant

- 100% Solids

- Low Odor

- High Strength

- High Build

- Superior Adhesion

- Chemical Resistant

- Wear Resistant

- Choice of Colors

Interested in a Temper-Crete system or Epoxy Mortar system for your upcoming job?

To learn more about our urethane cement system and finishes, visit us at https://www.westcoat.com/systems/temper-crete/. To learn more about our Epoxy Mortar system, visit us at https://www.westcoat.com/systems/epoxy-mortar/. You may also contact us at (800) 250-4519 to speak to a local representative in your area.